RCA of Steam Trap Failures

Steam trap failures are a significant issue in petrochemical plants, where steam is extensively used for heating, power generation, and driving chemical reactions. A steam trap's role is to release condensed steam (condensate) without allowing live steam to escape, maintaining efficient operation of the steam distribution system. When a steam trap fails—either by leaking, not discharging condensate, or being stuck open or closed—this can lead to multiple operational issues.

Failed traps can result in wasted steam, energy loss, unplanned shutdowns, and increased wear on system components. In more critical cases, condensate back-up from an undersized or inadequately performing steam trap can increase the risk of water hammer, equipment damage, and even catastrophic failures, impacting both safety and production continuity.

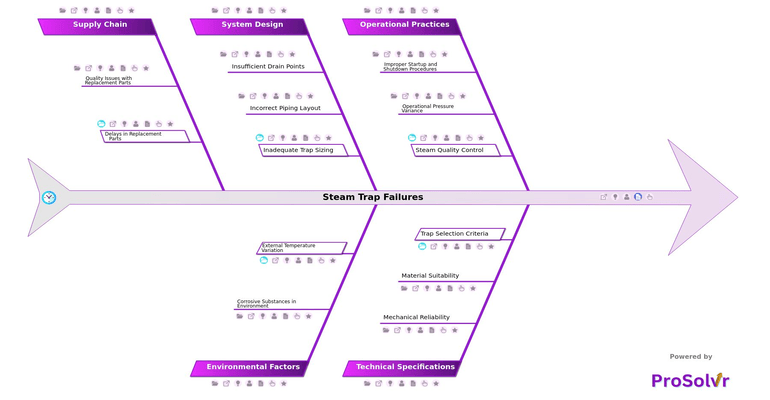

In a complex system, multiple factors contribute to steam trap failures. Improper startup and shutdown procedures can create operational stresses on traps, accelerating wear. Operational pressure variance is another factor that can misalign a trap's functioning if it wasn’t designed to handle varying pressures. Technical issues like material suitability and mechanical reliability of the trap also play a role; traps made from improper materials might degrade in petrochemical environments where corrosion is prevalent.

Additionally, external factors, such as corrosive substances in the environment or extreme temperatures affecting the trap lifespan, add further challenges. Compounding these issues, supply chain problems, including quality issues with replacement parts can make maintenance more difficult.

Addressing these failures effectively after they occur requires a structured root cause analysis (RCA). Using GEN-AI to facilitate RCA through tools like a fishbone diagram, integrated with Six Sigma principles, can provide systematic insight into the incident. A GEN AI-powered quality tool like ProSolvr can break down causes and arrange them in various categories, making it easier to identify areas where corrective and preventive actions (CAPA) should be implemented. For each identified root cause, specific actions can be developed and implemented to prevent recurrence, providing permanent solutions to the issue.

Who can learn from the Steam Trap Failures template?

- Maintenance Teams: Maintenance personnel can use the templates to identify causes of steam trap issues, implement corrective actions, and create preventive maintenance schedules to reduce unplanned downtime.

- Operations Staff: Operators can learn about best practices for startup, shutdown, and routine steam system management, ensuring that operational procedures support steam trap reliability and efficiency.

- Engineering and Design Teams: Engineers can use these templates to improve system design, sizing, and material specifications for steam traps, ensuring that designs are optimized for the operating environment and system demands.

- Procurement and Supply Chain Managers: Supply chain teams can learn about the importance of sourcing high-quality parts, assessing supplier reliability, and ensuring availability of critical components to avoid delays in replacement parts.

- Quality and Reliability Professionals: Quality assurance teams can use this information to establish quality control processes and audits that verify proper steam trap installation, selection, and material suitability for the operating environment.

- Health, Safety, and Environment (HSE) Managers: HSE professionals can understand the impact of steam trap failures on safety and environmental compliance, ensuring that preventive measures are in place to reduce the risks of leaks, water hammer, and associated safety hazards.

Why use this template?

Through GEN-AI-powered root cause analysis with a visual RCA tool like ProSolvr, petrochemical plants get a structured investigation of their issues for efficient problem-solving and enhanced reliability. The analysis with Six Sigma principles can minimize errors, leading to greater safety in operations. By focusing on CAPA based on the identified causes, plants can build resilience against future failures and create a proactive culture for continuous improvement in steam system management.

For efficient root cause analysis and enhanced operational reliability in your petrochemical plant, use ProSolvr by smartQED today!