RCA of Rotating Equipment Failures

Rotating equipment, including pumps, compressors, turbines, and motors, plays a critical role in maintaining process flows, pressure control, and overall plant productivity in petrochemical plants. Failures in these systems can result in costly downtime, safety hazards, and environmental risks. Common causes of these failures include seal degradation due to misalignment, excessive pressure, and poor material selection; wear and tear from component fatigue or bearing failure due to overloading; and improper lubrication, often caused by contaminated or insufficient lubricant. Environmental factors, such as temperature extremes and external vibrations, further contribute to increased operational risks and equipment stress.

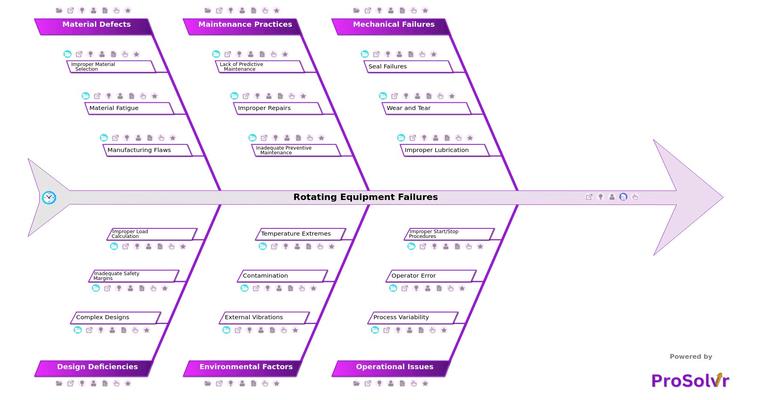

Addressing these failures requires a systematic approach to root cause analysis (RCA). Advanced tools like ProSolvr, which integrates fishbone diagrams into RCA, enable teams to visually categorize and map interconnected causes, including mechanical failures, operational issues, and maintenance practices. This structured RCA approach ensures no potential cause is overlooked, helping stakeholders identify the critical factors behind equipment failure and implement corrective and preventive actions (CAPA) effectively.

Inadequate predictive maintenance, such as failing to monitor oil conditions or perform vibration analysis, is a key contributor to rotating equipment failures. ProSolvr helps pinpoint maintenance gaps quickly, enabling organizations to optimize schedules and take corrective actions before failures occur. Similarly, RCA can uncover operational errors, such as improper shutdown procedures or failure to monitor critical parameters, often stemming from insufficient training or non-compliance with procedures. By integrating ProSolvr into plant workflows, these issues can be addressed efficiently, improving maintenance practices and enhancing equipment reliability.

By using ProSolvr for RCA, petrochemical plants can foster a culture of continuous improvement. The visual mapping and data-driven insights allow teams to systematically identify causes and develop targeted CAPA, reducing risks and ensuring long-term operational excellence. This structured approach helps improve equipment performance, reduce downtime, and increase operational efficiency, ultimately enhancing overall plant reliability, safety, and productivity.

Who can learn from the Rotating Equipment Failures template?

- Maintenance Engineers: They can use the template to systematically investigate failures, identify the root causes, and plan maintenance activities that prevent future issues.

- Operations Managers: They can utilize the template to understand how operational practices may contribute to equipment failures and implement corrective actions to optimize processes.

- Reliability Engineers: These professionals can apply the template to improve equipment reliability by analyzing failure data and developing strategies to enhance the performance and lifespan of rotating equipment.

- Plant Supervisors and Technicians: They can use the template as a guide during troubleshooting and failure investigations, ensuring that all potential causes are considered.

- Safety Officers: They can employ the template to assess how equipment failures might impact plant safety and to develop strategies that mitigate risks associated with such failures.

- Design Engineers: They can use the template to review design-related failures and improve the design specifications for future equipment to ensure they meet operational demands.

- Quality Assurance Teams: They can leverage the template to investigate failures linked to design flaws or poor material selection, ensuring higher quality standards are met in future projects.

Why use this template?

Conducting Root Cause Analysis (RCA) for rotating equipment failures using a fishbone diagram is an effective method to identify all contributing factors. ProSolvr, a powerful visual RCA tool, simplifies this process by helping teams visualize how different factors interrelate, making it easier to pinpoint the underlying causes rather than just addressing symptoms. By categorizing and analyzing each failure factor, ProSolvr enables teams to implement targeted corrective actions, preventing future failures and improving the reliable operation of rotating equipment. This leads to reduced downtime, enhanced plant productivity, and greater overall operational efficiency.

Use ProSolvr by smartQED for a detailed analysis of equipment if your plant for efficient problem resolution