RCA of Reactor Pressure Fluctuation

Reactor pressure fluctuation is a critical challenge in petrochemical plants, often disrupting chemical reactions, compromising product quality, and posing significant safety risks. These fluctuations arise due to irregularities in pressure regulation systems within reactors, which can lead to inefficiencies, costly downtimes, and even catastrophic failures.

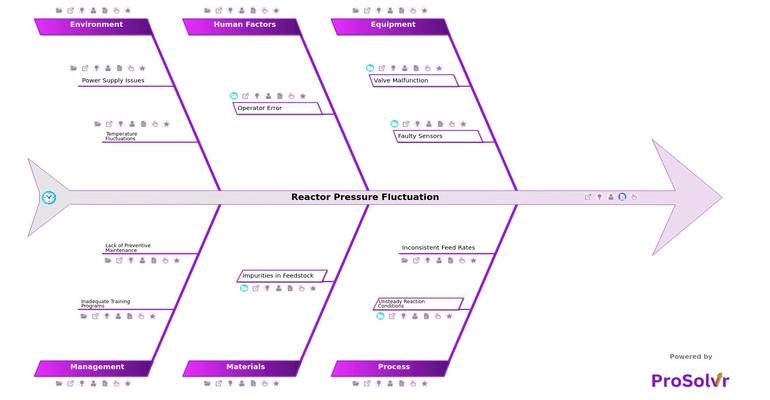

Common causes include equipment malfunctions such as valve malfunction, sticking of control valves, and faulty sensors due to wear and tear or incorrect calibration. On the process side, unsteady reaction conditions, fluctuating catalyst activity, poor temperature control, and inconsistent feed rates significantly contribute to pressure instability. Human factors, like operator error and inadequate training, along with material issues like impurities or contaminants in feedstock, can further compound the problem. Additionally, environmental factors, such as power supply disruptions and temperature fluctuations, and management lapses, such as lack of preventive maintenance, can exacerbate reactor instability.

For instance, a poorly calibrated sensor may fail to detect pressure deviations accurately, leading to delayed corrective actions. Similarly, sticking control valves may hinder precise pressure adjustments, disrupting reaction stability. Unsteady reaction conditions caused by fluctuating catalyst activity can further intensify pressure irregularities, making it difficult to achieve consistent output.

To address these issues effectively, ProSolvr, a GEN-AI-powered root cause analysis application based on fishbone diagrams and Six Sigma methodologies, offers a cutting-edge solution. ProSolvr enables teams to categorize potential causes—equipment, process, human factors, materials, environment, and management—and visually map the problem. By identifying root causes, ProSolvr empowers teams to implement targeted corrective actions, ensuring efficient and sustainable reactor operations while mitigating future risks

Who can learn from the Reactor Pressure Fluctuation template?

- Reactor Operators: Operators can learn how to identify and mitigate issues related to pressure fluctuations, improving their ability to maintain stable reactor conditions. They can also better understand the root causes of fluctuations to avoid recurrence.

- Maintenance Teams: Maintenance personnel can learn to troubleshoot and fix equipment malfunctions such as faulty valves or sensors that contribute to pressure instability. They can also implement more effective preventive maintenance schedules.

- Process Engineers: Engineers can learn to optimize reaction conditions and refine process parameters to prevent pressure fluctuations. They can integrate findings into improving overall reactor performance and stability.

- Quality Control Teams: Quality control personnel can understand how feedstock impurities and fluctuations in feed rates can impact reactor pressure. This knowledge helps them implement stricter quality assurance measures on incoming materials.

- Management and Training Coordinators: Management can learn the importance of implementing strong training programs and regular maintenance to prevent pressure issues. They can use RCA insights to enhance long-term operational procedures and reduce unplanned downtimes.

Why use this template?

The structured problem-solving approach of a visual quality tool like ProSolvr can help teams develop preventive measures to avoid future reactor pressure fluctuations. Inadequate maintenance programs or lack of preventive measures are often management-related causes that, once identified, can lead to stronger, more proactive maintenance schedules and improved training systems. By utilizing GEN-AI and Six Sigma methodologies, organizations can ensure that the corrective and preventive actions (CAPA) are not only rooted in data but also focus on long-term process stability, leading to more efficient and safe operations.

Discover how ProSolvr by smartQED can streamline root cause analysis in petrochemical plants, helping you identify issues faster and implement effective solutions. Enhance operational efficiency with data-driven insights and actionable corrective actions.