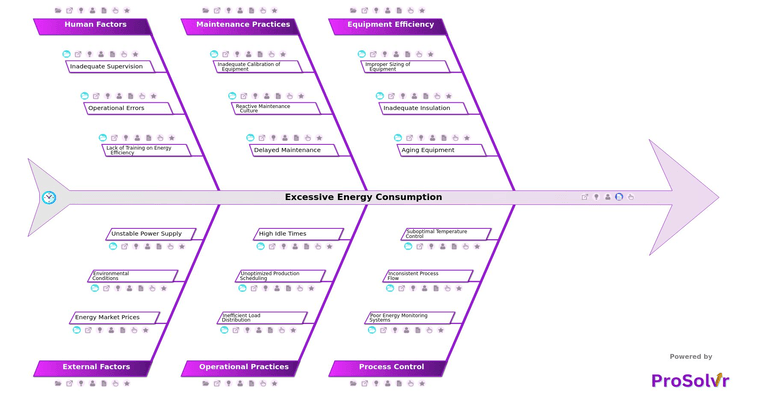

RCA of Excessive Energy Consumption

Excessive energy consumption in petrochemical plants poses significant challenges, impacting operational efficiency, costs, and environmental sustainability. Core processes such as heating, cooling, and chemical reactions demand substantial energy, but inefficiencies can lead to higher expenses, increased carbon emissions, and resource strain.

Several factors contribute to these inefficiencies. Equipment-related issues, such as underutilized machinery or oversized equipment for specific processes, result in wasted energy. Inadequate insulation, including missing or degraded materials, causes significant heat loss. Additionally, aging equipment often lacks modern energy-saving features, leading to inefficiency.

Process control problems further exacerbate the issue. Inconsistent process flows, with poorly synchronized operations and fluctuating input-output rates, increase energy demands. Suboptimal temperature control, such as deviations from optimal settings or inefficient heat exchange processes, not only wastes energy but also compromises product quality and process stability.

Maintenance practices also play a critical role. Reactive maintenance or delayed repairs contribute to energy inefficiencies by causing unexpected breakdowns and extended downtime. Similarly, inadequate calibration of equipment results in suboptimal performance and incorrect energy usage data.

An RCA tool like ProSolvr can significantly aid in addressing excessive energy consumption in petrochemical plants by systematically identifying root causes of inefficiencies. To tackle excessive energy consumption, a GEN-AI-powered Root Cause Analysis (RCA) using fishbone diagrams and Six Sigma principles is essential.

ProSolvr help categorize inefficiencies and pinpoint root causes across equipment, processes, and operational practices. supports the development of effective corrective and preventive measures by organizations, promoting operational excellence and cost efficiency. This systematic approach ensures energy-efficient operations, reduced downtime, and progress toward sustainability goals.

Who can learn from the Excessive Energy Consumption template?

- Plant Operators: Operators can learn to identify energy inefficiencies during regular operations. Understanding root causes can help them optimize processes to reduce energy consumption.

- Maintenance Technicians: Maintenance staff can identify areas where equipment wear contributes to energy inefficiency. They can focus on preventive maintenance to ensure energy-efficient operations.

- Energy Managers: Energy managers can develop strategies to monitor and control energy use effectively. The RCA can help them prioritize energy-saving initiatives based on root causes.

- Production Supervisors: Supervisors can learn to align production schedules with energy-efficient practices. They can optimize shift patterns and ensure minimal idle time to conserve energy.

- Procurement and Equipment Managers: These teams can recognize the importance of selecting properly sized and energy-efficient equipment. They can adjust procurement strategies to reduce excess energy consumption from oversized machinery.

- Environmental and Sustainability Teams: These teams can use the RCA to target energy-saving projects aligned with sustainability goals. They can advocate for practices that reduce overall energy consumption and environmental impact.

Why use this template?

The consequences of excessive energy consumption in petrochemical plants extend beyond financial losses. Increased operational costs can erode profit margins, while elevated energy use contributes to higher greenhouse gas emissions, undermining sustainability goals. However, the insights gained from a visual GEN-AI powered root cause analysis enable the formulation of a detailed CAPA (Corrective and Preventive Action) plan. The structured approach of an RCA not only resolves immediate issues but also ensures long-term energy optimization in petrochemical plants.

Unlock the full potential of your petrochemical plant with ProSolvr a GEN-AI-driven Root Cause Analysis application by smartQED. Optimize energy consumption, enhance efficiency, and drive sustainable operations today!