RCA of Reactor Catalyst Deactivation

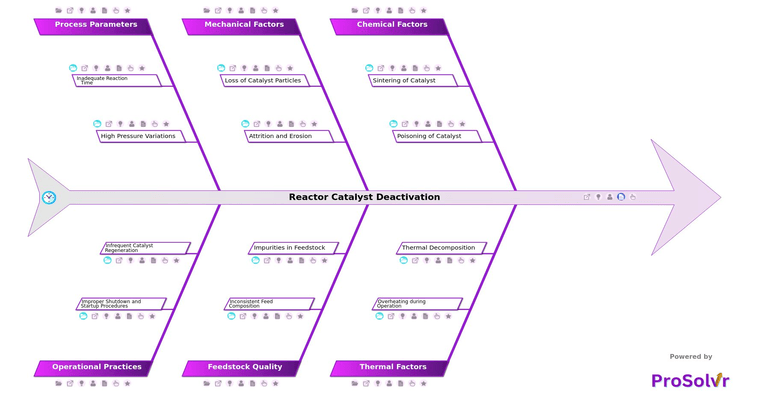

Reactor catalyst deactivation is a major challenge in petrochemical plants, where catalysts play a critical role in facilitating chemical reactions under controlled conditions. Over time, catalysts lose effectiveness due to factors such as chemical, thermal, mechanical, and feedstock-related causes. This results in slower reactions, undesirable process shifts, reduced efficiency, suboptimal yields, and potential safety risks.

For instance, sintering of the catalyst, a chemical factor, occurs at high temperatures and leads to the loss of active sites due to catalyst particle coarsening, which reduces the surface area necessary for effective reactions. Similarly, poisoning of the catalyst by contaminants like sulfur or chlorine in feedstock can result in coke formation, blocking catalytic sites and diminishing activity. Thermal factors, such as localized overheating, disrupt temperature uniformity and degrade catalyst structure, while mechanical factors like attrition, erosion, or particle loss physically diminish the catalyst's presence and impact.

To address these issues, ProSolvr, a GEN-AI-powered root cause analysis application based on fishbone (Ishikawa) diagrams and Six Sigma principles, offers a structured solution. ProSolvr systematically examines all potential deactivation factors, enabling teams to identify root causes such as sintering, poisoning, or overheating. By visually mapping problems and isolating specific issues, ProSolvr provides actionable insights into deviations from optimal operating conditions.

Leverage ProSolvr to pinpoint root causes and implement lasting solutions, ensuring improved catalyst performance and sustained operational efficiency while solving challenges for good.

Who can learn from the Reactor Catalyst Deactivation template?

- Process Engineers: They are responsible for optimizing reactor operations and ensuring that catalysts function at peak efficiency. By understanding the causes of catalyst deactivation and applying RCA, they can improve process parameters, optimize reaction conditions, and implement preventive measures to minimize catalyst issues.

- Maintenance Teams: The teams play a crucial role in inspecting, repairing, and maintaining reactor equipment and catalysts. By learning from the RCA, they can better identify and address mechanical failures or attrition that contribute to catalyst loss, as well as monitor and repair components that impact catalyst performance.

- Operations Managers: They oversee the overall functioning of the plant and are responsible for ensuring smooth, efficient operations. By understanding RCA findings, they can enforce best practices, implement proper shutdown/startup procedures, and schedule catalyst regeneration to prevent deactivation, thus improving plant productivity and safety.

- Quality Control (QC) and Quality Assurance (QA) Teams: The teams are tasked with ensuring feedstock quality and consistency. They can use the insights from the RCA to tighten feedstock monitoring processes, improve impurity detection, and implement better screening and purification techniques to prevent catalyst poisoning from contaminants like sulfur and chlorine.

- Catalyst Suppliers and Researchers: The suppliers and researchers can learn from the RCA to improve the design and manufacturing of catalysts. By understanding the common causes of deactivation (e.g., sintering, poisoning, thermal decomposition), they can develop more durable, efficient catalysts that resist deactivation under harsh operating conditions.

- Training and Development Teams: Training and development teams are responsible for educating plant personnel on safe, efficient practices. By incorporating lessons learned from the RCA into their training programs, they can ensure that operators and engineers are better equipped to manage catalyst deactivation issues and apply corrective actions when needed.

Why use this template?

With a well-conducted RCA, teams can then develop a CAPA (Corrective and Preventive Action) plan to address both immediate fixes and long-term safeguards. This kind of GEN-AI driven RCA with a quality tool like ProSolvr, grounded in Six Sigma’s emphasis on quality and process control, provides a thorough, actionable framework to not only correct current problems but to establish preventive measures to mitigate future risks, improving overall reactor efficiency and stability.

Empower your team withProSolvr by smartQEDto drive sustained improvements in productivity, safety, and cost-efficiency in your petrochemical plant.