RCA for Pump Failure in Petrochemical Plants

Pump failures in petrochemical plants are complex, often requiring a mix of technical expertise, operational vigilance, and proactive maintenance to prevent and mitigate issues. These failures can lead to significant operational disruptions, safety hazards, and financial losses.

Pumps are essential for transporting fluids like crude oil, chemicals, and other products through various processing stages. Numerous issues, such as bearing failure due to improper lubrication or impeller erosion from cavitation, can disrupt pump operation. These problems often result in noise, vibration, and ultimately, pump failure. Hydraulic issues, such as cavitation, where vapor bubbles form due to low-pressure conditions, can also cause significant damage.

Consequences of Pump Failures in Petrochemical Plants

- Production Loss: Unplanned shutdowns can result in significant production losses and delays.

- Safety Hazards: Leaks, spills, or pressure surges caused by pump failures can create hazardous conditions, potentially leading to fires, explosions, or toxic releases.

- Environmental Impact: Fluid leaks due to pump failure can contaminate soil, water, and air, leading to environmental damage and regulatory penalties.

- Increased Maintenance Costs: Frequent pump failures can lead to higher repair costs, increased spare parts inventory, and additional labor requirements.

- Reputation Damage: Persistent pump failures can damage the reputation of the plant and the company, especially if they result in safety incidents or environmental violations.

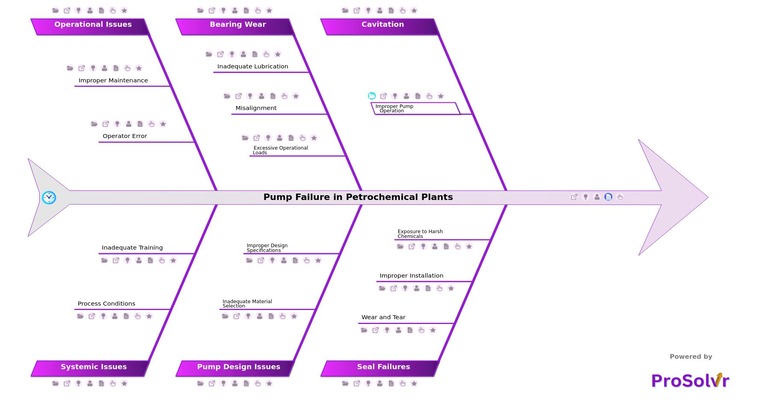

A root cause analysis (RCA), using the Six Sigma principles can be a critical tool in addressing pump failures in petrochemical plants by identifying the underlying causes rather than just treating the symptoms. By systematically investigating pump failures, a visual RCA tool like ProSolvr helps to uncover the specific factors—whether mechanical, operational, or environmental—that contributed to the issue. This process typically involves gathering data, analyzing pump performance, and examining maintenance records to trace back the sequence of events leading to the failure. By pinpointing the root cause, whether it’s improper lubrication, material corrosion, or operational errors, RCA enables the implementation of targeted corrective, preventive and investigative actions that directly address the source of the problem.

Who can learn from the Pump Failure in Petrochemical Plants template?

Root Cause Analysis (RCA) of pump failure in petrochemical plants provides valuable insights for various stakeholder

- Maintenance Technicians and Engineers: These individuals can learn from RCA by gaining insights into the specific causes of pump failures and how to address them effectively. Understanding the root causes helps in refining maintenance procedures, improving troubleshooting techniques, and preventing future issues.

- Process Engineers: They can use RCA findings to adjust process parameters or redesign systems to minimize factors contributing to pump failures. This knowledge helps in optimizing pump performance and ensuring that the process conditions are within safe operational limits.

- Operations Personnel: Operators who interact with pumps daily can benefit from RCA by learning about best practices for pump operation, recognizing early warning signs of potential failures, and adhering to proper start-up and shut-down procedures.

- Quality Control and Assurance Teams: These teams can apply RCA findings to improve quality control measures, ensuring that pumps and related components meet the required standards and are less likely to experience failure due to manufacturing defects or material issues.

- Management and Plant Leadership: Understanding the outcomes of RCA allows management to make informed decisions about resource allocation, maintenance budgets, and investments in new technology or training programs. It also highlights the importance of fostering a culture of continuous improvement and safety.

- Training and Development Specialists: These specialists can use RCA insights to develop more effective training programs for all relevant personnel, focusing on areas identified as contributing to pump failures. Improved training ensures that staff are better prepared to handle equipment issues and reduce the likelihood of future failures.

Why use this template?

Implementing a Gen-AI powered RCA in pump failure incidents not only helps in preventing recurrence but also enhances overall plant reliability and safety. By addressing the fundamental issues uncovered during the analysis, petrochemical plants can improve maintenance practices, optimize pump design and operation, and refine training programs for personnel. This proactive approach reduces the likelihood of future failures, minimizes downtime, and mitigates the risk of safety hazards, ultimately leading to more efficient and safer plant operations.

Draft and create a template for problem analysis in ProSolvr by smartQED.