Root Cause Analysis of Machining Tolerance Issues

Machining tolerance issues arise when the dimensions or finishes of machined parts deviate from specified standards, leading to imperfections that compromise performance, safety, and reliability. In the automotive industry, such issues can result in component failure, reduced efficiency, higher maintenance costs, and safety hazards. Problems like tool wear from inappropriate materials, inconsistent coolant flow causing overheating, and misaligned machine components during setup often lead to dimensional inaccuracies in critical parts like engine blocks, transmission gears, or braking systems.

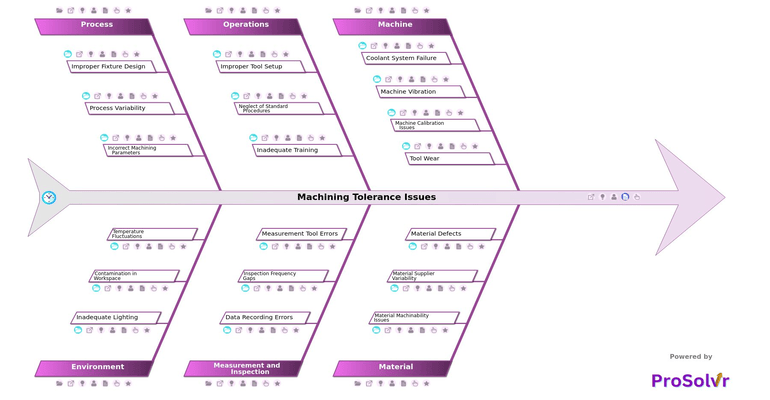

The fishbone diagram categorizes causes into six key areas: Machine, Material, Operations, Measurement and Inspection, Process, and Environment. Machine-related issues include clogged coolant nozzles, unstable bases causing vibration, and misaligned components due to missed calibration schedules. Material defects like improper heat treatment, excessive hardness, or internal cracks can impact machinability. Operational errors, such as improper clamping, failure to follow setup protocols, or inadequate operator training, often contribute. Other factors include damaged measuring tools, poor fixture design, inconsistent machining parameters, and environmental factors like temperature fluctuations or workspace contamination.

For instance, inconsistent coolant flow leading to overheating might be traced to clogged coolant nozzles caused by inadequate maintenance protocols. Similarly, improper clamping causing movement during operation may result from operators skipping setup procedures due to insufficient training. Such deviations can disrupt production schedules, increase the risk of costly recalls, and damage brand reputation. Addressing these problems requires a detailed and systematic root cause analysis to identify and eliminate underlying inefficiencies.

ProSolvr, a GEN-AI-powered root cause analysis tool, provides a structured approach to solving machining tolerance issues. By leveraging fishbone diagrams aligned with Six Sigma principles, ProSolvr helps identify root causes across categories like Machine, Material, and Operations. For example, it can analyze maintenance practices, material quality, and operator behavior to pinpoint specific issues and recommend corrective and preventive actions (CAPA). This approach not only resolves current problems but also enhances process reliability by standardizing procedures, updating training modules, and improving quality controls. With ProSolvr, manufacturers can ensure high-quality outputs, reduce costs, and achieve operational excellence.

Machining Tolerance Issues

- Machine

- Coolant System Failure

- Clogged or damaged coolant nozzles

- Use of improper coolant for specific materials

- Inconsistent coolant flow leading to overheating

- Machine Vibration

- Lack of vibration dampening mechanisms

- Inadequate floor mounting or unstable base

- Worn-out machine components increasing vibrations

- Machine Calibration Issues

- Use of outdated calibration standards

- Calibration schedules not adhered to

- Misaligned machine components during setup

- Tool Wear

- Inappropriate tool materials for the job

- Tool not replaced within recommended intervals

- Dull cutting tools causing inconsistent dimensions

- Coolant System Failure

- Material

- Material Machinability Issues

- Materials with inconsistent grain structures

- Improper heat treatment of materials before machining

- Excessive material hardness requiring higher force

- Material Supplier Variability

- Delay in material inspection upon arrival

- Inadequate supplier quality checks

- Non-standardized material specifications from suppliers

- Material Defects

- Improper material storage causing corrosion

- Variability in raw material hardness

- Internal cracks or voids in raw materials

- Material Machinability Issues

- Operations

- Improper Tool Setup

- Failure to inspect tools for defects before use

- Improper clamping leading to movement during operation

- Incorrect positioning of cutting tools

- Neglect of Standard Procedures

- Operator fatigue leading to errors

- Skipping critical pre-machining checks

- Failure to follow documented setup protocols

- Inadequate Training

- Limited awareness of material behavior during machining

- Insufficient understanding of machining parameters

- Operators lacking proper knowledge of machine settings

- Improper Tool Setup

- Measurement and Inspection

- Data Recording Errors

- Data loss due to inadequate digital record-keeping

- Misinterpretation of measurement specifications

- Manual entry errors during measurement recording

- Inspection Frequency Gaps

- Inadequate inspection of key features

- Random sampling instead of comprehensive inspection

- Long intervals between tolerance checks

- Measurement Tool Errors

- Incorrect zero-point settings on instruments

- Damaged or worn measurement tools causing inaccuracies

- Use of uncalibrated measuring instruments

- Data Recording Errors

- Process

- Improper Fixture Design

- Fixtures not designed for specific material properties

- Inaccurate fixture alignment leading to errors

- Fixtures not providing adequate support for workpieces

- Process Variability

- Variability in machining programs due to version differences

- Lack of process standardization across shifts

- Inconsistent cycle times causing dimensional differences

- Incorrect Machining Parameters

- Lack of adaptive control for varying material conditions

- Incorrect depth of cut settings

- Use of inappropriate cutting speeds and feeds

- Improper Fixture Design

- Environment

- Inadequate Lighting

- Inadequate inspection conditions reducing measurement accuracy

- Shadows or glare interfering with tool alignment

- Poor visibility leading to errors in setup and inspection

- Contamination in Workspace

- Environmental vibrations from nearby heavy machinery

- Oil or coolant spills affecting equipment stability

- Dust or debris interfering with precision machining

- Temperature Fluctuations

- Use of machines outside recommended operating temperature

- Lack of temperature control in machining area

- Changes in ambient temperature affecting machine accuracy

- Inadequate Lighting

Suggested Actions Checklist

Here are some corrective actions, preventive actions and investigative actions that organizations may find useful:

- Machine

- Coolant System Failure

- Corrective Actions:

- Clean or replace clogged/damaged nozzles.

- Ensure proper coolant type is used for specific materials.

- Adjust coolant flow to ensure consistency and prevent overheating.

- Preventive Actions:

- Regularly inspect and clean coolant nozzles.

- Establish a coolant management system to match materials with the correct coolant.

- Implement routine checks of coolant flow and temperature to ensure stability.

- Investigative Actions:

- Investigate root cause of nozzle blockages and damaged components.

- Review material specifications and coolant compatibility.

- Monitor coolant flow and temperature to identify inconsistencies.

- Corrective Actions:

- Machine Vibration

- Corrective Actions:

- Install or replace vibration dampening mechanisms.

- Secure machine on stable floor mountings.

- Replace worn-out components contributing to vibrations.

- Preventive Actions:

- Perform regular checks of machine base and mounting stability.

- Set up regular inspections of machine components to detect wear early.

- Integrate vibration damping as a standard feature in machinery design.

- Investigative Actions:

- Measure vibration levels across various machine components.

- Analyze vibration frequencies to identify specific worn-out or loose components.

- Review machine foundation design and location for stability.

- Corrective Actions:

- Machine Calibration Issues

- Corrective Actions:

- Update to the latest calibration standards.

- Correct any misaligned components during setup.

- Follow calibration schedules strictly to prevent deviation.

- Preventive Actions:

- Create a regular machine calibration and maintenance schedule.

- Train personnel on calibration procedures and standards.

- Develop a checklist for machine setup to ensure proper calibration.

- Investigative Actions:

- Review historical calibration records for deviations.

- Inspect alignment of critical machine components.

- Audit calibration schedule adherence and the process used.

- Corrective Actions:

- Tool Wear

- Corrective Actions:

- Replace tools that have reached the end of their recommended life.

- Use appropriate tools for the specific machining task.

- Sharpen or replace dull cutting tools to restore precision.

- Preventive Actions:

- Establish tool replacement and maintenance intervals based on usage.

- Monitor tool wear through regular inspections during operations.

- Standardize tool materials for specific machining tasks to reduce wear.

- Investigative Actions:

- Review tool usage and performance records to detect early wear.

- Investigate improper machining conditions that may contribute to excessive wear.

- Analyze cutting conditions (speed, feed rate) for optimal tool longevity.

- Corrective Actions:

- Coolant System Failure

- Material

- Material Machinability Issues

- Corrective Actions:

- Assess material properties and switch to alternative materials if necessary.

- Reprocess materials that have undergone improper heat treatment.

- Adjust machining parameters to accommodate higher material hardness.

- Preventive Actions:

- Conduct thorough material testing before machining to ensure proper machinability.

- Develop a consistent heat treatment process for materials before machining.

- Optimize cutting parameters for materials of varying hardness.

- Investigative Actions:

- Investigate supplier material certificates and manufacturing processes.

- Analyze the effect of material properties on cutting performance.

- Review machining parameters in relation to material behavior.

- Corrective Actions:

- Material Supplier Variability

- Corrective Actions:

- Implement tighter incoming material inspection processes.

- Work closely with suppliers to standardize material specifications.

- Implement corrective measures when material non-conformance is identified.

- Preventive Actions:

- Set up a supplier quality management system to ensure consistent material quality.

- Conduct periodic audits of suppliers to assess compliance with standards.

- Establish material inspection protocols upon arrival.

- Investigative Actions:

- Investigate the cause of material inconsistencies from suppliers.

- Audit past shipments for recurring material quality issues.

- Track material performance over time to identify trends or patterns.

- Corrective Actions:

- Material Defects

- Corrective Actions:

- Replace or rework materials exhibiting defects.

- Improve storage practices to prevent material corrosion.

- Remove materials with visible internal cracks or voids.

- Preventive Actions:

- Implement proper storage conditions to minimize corrosion risk.

- Use non-destructive testing methods to detect material defects early.

- Work with suppliers to ensure better control over material properties.

- Investigative Actions:

- Inspect storage conditions to identify root causes of material corrosion.

- Perform material defect analysis using X-ray or ultrasonic testing.

- Track defect occurrences to identify potential patterns in raw material batches.

- Corrective Actions:

- Material Machinability Issues

- Operations

- Improper Tool Setup

- Corrective Actions:

- Inspect all tools before use for defects or damage.

- Re-secure or re-align cutting tools to prevent movement during operation.

- Correct the positioning of tools according to operation requirements.

- Preventive Actions:

- Establish standardized tool inspection protocols before each operation.

- Train operators on proper tool handling and setup procedures.

- Implement automatic clamping systems to prevent tool misalignment.

- Investigative Actions:

- Review tool setup procedures and operator adherence.

- Conduct root cause analysis for repeated tool setup errors.

- Measure tool alignment accuracy using digital tools or gauges.

- Corrective Actions:

- Neglect of Standard Procedures

- Corrective Actions:

- Re-train operators on proper setup and machining procedures.

- Reinforce the importance of pre-machining checks and inspections.

- Re-validate setup protocols and ensure compliance during operation.

- Preventive Actions:

- Schedule regular refresher training sessions for operators on key procedures.

- Implement a checklist system to ensure all pre-machining steps are followed.

- Enforce adherence to documented procedures via audits and supervision.

- Investigative Actions:

- Review incidents of missed steps or errors to identify root causes.

- Investigate operator fatigue levels or other factors contributing to errors.

- Evaluate the clarity and accessibility of written setup procedures.

- Corrective Actions:

- Inadequate Training

- Corrective Actions:

- Provide comprehensive training on material behavior, machine settings, and machining parameters.

- Ensure operators understand the full range of machine functions.

- Increase hands-on training to improve skill levels.

- Preventive Actions:

- Establish ongoing training programs for new and existing operators.

- Use job-specific training materials for different machine types and materials.

- Implement knowledge checks to ensure understanding of key operational factors.

- Investigative Actions:

- Review training records to identify gaps in knowledge.

- Interview operators to assess the level of training and understanding.

- Analyze machine or operational failures that may be due to training deficiencies.

- Corrective Actions:

- Improper Tool Setup

- Measurement and Inspection

- Data Recording Errors

- Corrective Actions:

- Implement a robust digital record-keeping system to avoid data loss.

- Recalibrate measurement systems if manual entry errors are identified.

- Rectify discrepancies by verifying recorded data against actual measurements.

- Preventive Actions:

- Set up automated data entry and storage systems to reduce manual errors.

- Regularly train operators on proper data recording techniques.

- Use redundant data capture methods (e.g., digital and manual) for verification.

- Investigative Actions:

- Audit past data entry and recording systems for accuracy and consistency.

- Investigate instances of missing or incorrect data to identify root causes.

- Evaluate data storage and retrieval systems for potential technical issues.

- Corrective Actions:

- Inspection Frequency Gaps

- Corrective Actions:

- Increase inspection frequency for key features to ensure consistency.

- Implement real-time monitoring to reduce reliance on periodic inspections.

- Adjust inspection protocols to ensure critical dimensions are checked more regularly.

- Preventive Actions:

- Develop a comprehensive inspection schedule for all critical features.

- Establish automated inspection systems with real-time feedback for operators.

- Implement a tracking system for inspection intervals to ensure timely checks.

- Investigative Actions:

- Investigate the reasons for gaps in inspection frequency and review any deviations.

- Analyze historical data to see if frequency gaps contributed to defects or variations.

- Audit previous inspection schedules and compliance adherence.

- Corrective Actions:

- Measurement Tool Errors

- Corrective Actions:

- Repair or replace damaged or worn measurement tools.

- Recalibrate measurement instruments and reset zero points.

- Verify measurement tool accuracy before use and ensure proper calibration.

- Preventive Actions:

- Regularly maintain and inspect measurement tools to detect early signs of wear.

- Establish calibration schedules and assign responsible personnel for tool upkeep.

- Train operators on how to handle measurement tools properly and ensure proper zero-point settings.

- Investigative Actions:

- Investigate past instances of measurement errors linked to faulty tools.

- Analyze tool calibration records and identify patterns of inaccuracies.

- Inspect measurement tools for wear and tear, particularly after high-frequency usage.

- Corrective Actions:

- Data Recording Errors

- Process

- Improper Fixture Design

- Corrective Actions:

- Redesign fixtures to accommodate specific material properties and machining needs.

- Adjust fixture alignment to ensure accuracy during machining operations.

- Reinforce or upgrade fixtures to provide better support for workpieces.

- Preventive Actions:

- Integrate standardized fixture design protocols that align with material properties.

- Implement regular checks for fixture alignment and support before machining.

- Conduct training for operators on fixture handling and setup to ensure correct use.

- Investigative Actions:

- Review fixture design specifications and compare them against operational needs.

- Investigate instances where improper fixture design led to dimensional inaccuracies.

- Analyze fixture design failures and identify recurring issues or design flaws.

- Corrective Actions:

- Process Variability

- Corrective Actions:

- Standardize machining programs across shifts and machines.

- Develop and implement strict controls to minimize variation between processes.

- Review and adjust cycle times to ensure consistent quality and dimensions.

- Preventive Actions:

- Establish a process standardization plan to align machining parameters across shifts.

- Use version-controlled software for machining programs to prevent inconsistencies.

- Monitor process data regularly to identify and address any variability in cycle times.

- Investigative Actions:

- Investigate the root cause of inconsistencies in machining programs or cycle times.

- Review historical data to identify when process variability began.

- Analyze shift differences in process adherence and performance metrics.

- Corrective Actions:

- Incorrect Machining Parameters

- Corrective Actions:

- Recalculate cutting parameters (e.g., depth of cut, speed, and feed rate) based on material and tool requirements.

- Adjust settings to better suit the specific machining task.

- Implement immediate corrections to machining parameters to minimize impact on quality.

- Preventive Actions:

- Create a database of optimized machining parameters for different materials and tools.

- Train operators to properly adjust parameters based on real-time conditions.

- Implement adaptive control systems that adjust machining parameters automatically.

- Investigative Actions:

- Review historical records to identify patterns of incorrect parameter settings.

- Investigate specific instances of dimensional variation related to parameter choices.

- Analyze the effectiveness of the parameter adjustment process during setup and operation.

- Corrective Actions:

- Improper Fixture Design

- Environment

- Inadequate Lighting

- Corrective Actions:

- Install additional lighting or improve existing lighting in inspection and machining areas.

- Remove obstacles that block light or create shadows that interfere with setup or inspection.

- Adjust lighting angle and intensity to reduce glare and improve visibility.

- Preventive Actions:

- Conduct regular assessments of lighting conditions in all critical machining and inspection areas.

- Maintain a lighting maintenance schedule to replace bulbs and ensure optimal lighting.

- Integrate lighting standards into workstation design for better visibility.

- Investigative Actions:

- Investigate the impact of inadequate lighting on quality issues or setup errors.

- Audit lighting levels in critical work zones and compare them to industry standards.

- Assess operator feedback regarding visibility and its impact on performance.

- Corrective Actions:

- Contamination in Workspace

- Corrective Actions:

- Clean up oil, coolant, or dust contamination promptly to prevent interference with machining.

- Address environmental vibrations or other disturbances that affect machine performance.

- Improve ventilation or use air filtration systems to reduce workspace contamination.

- Preventive Actions:

- Set up routine cleaning protocols to ensure workspaces remain free of contaminants.

- Implement vibration isolation or damping for machines in proximity to heavy equipment.

- Conduct regular air quality checks to minimize dust, debris, and coolant buildup.

- Investigative Actions:

- Investigate the impact of contamination on machinery and product quality.

- Review cleaning and contamination control protocols to identify potential gaps.

- Analyze patterns of machine errors or defects that coincide with contamination incidents.

- Corrective Actions:

- Temperature Fluctuations

- Corrective Actions:

- Install or adjust temperature control systems to stabilize the working environment.

- Review machine operating ranges and ensure equipment is within the recommended temperature range.

- Adjust or replace equipment affected by temperature fluctuations to prevent malfunctions.

- Preventive Actions:

- Implement climate control systems in machining areas to minimize temperature variation.

- Conduct regular temperature checks to ensure the workspace stays within optimal ranges.

- Establish temperature monitoring systems for critical machines or equipment.

- Investigative Actions:

- Investigate correlations between temperature changes and performance or dimensional inaccuracies.

- Review historical temperature records and machine performance to identify patterns.

- Audit temperature control systems and machine specifications for discrepancies.

- Corrective Actions:

- Inadequate Lighting

Who can use the Machining Tolerance Issues template?

- Automotive Manufacturing Engineers: Engineers involved in designing and assembling vehicles can use the template to identify machining issues affecting critical components, ensuring performance and safety standards.

- Quality Control Specialists: Professionals responsible for inspection and compliance can learn from the detailed categories in the template. This aids in developing rigorous inspection protocols to minimize defects.

- Maintenance Technicians: Maintenance teams can use insights to focus on predictive and preventive maintenance, reducing downtime and improving equipment reliability.

- Production Line Supervisors: Supervisors can apply the lessons to ensure adherence to operational protocols and minimize operator errors. This fosters a culture of accountability and efficiency.

- Supplier Quality Managers: Suppliers providing raw materials or components can address various issues aligning their processes with client specifications and improving supply chain reliability.

- Training and Development Teams: Training teams can design targeted programs addressing gaps like ensuring operators and engineers are equipped with the necessary skills and knowledge.

Why use this template?

Applications like ProSolvr, designed for root cause analysis with fishbone diagram integration, can further streamline the problem-solving process. ProSolvr allows teams to visually map out potential causes and link them to observed effects, creating a comprehensive overview of the problem. By integrating Six Sigma principles, ProSolvr not only supports the identification of root causes but also helps teams establish measurable standards for improvement. This ensures that corrective actions address not just immediate symptoms but also systemic issues, fostering a culture of continuous improvement in machining and quality control processes within the automotive industry.

Ensure smooth functioning in your organization with ProSolvr by smartQED with efficient root cause analysis.