RCA of Land Subsidence

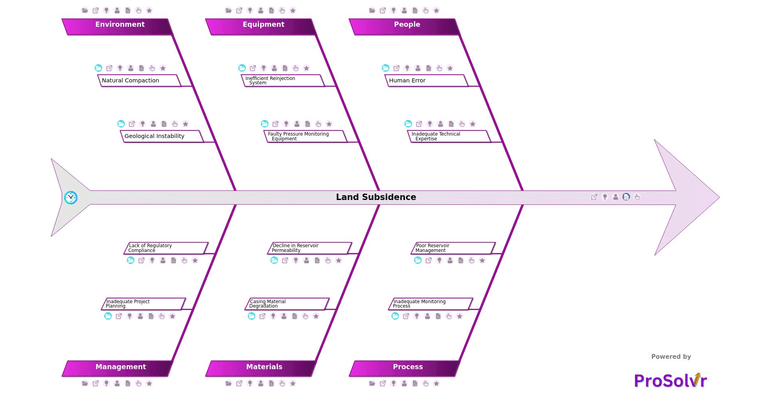

Land subsidence happens when the ground slowly sinks because too much geothermal water or steam is taken out from deep underground. When this underground pressure drops, the soil and rocks above start to settle. This settling becomes worse when people make mistakes, such as using the wrong injection pressure or interpreting well data incorrectly. It also becomes more likely when teams do not have enough technical training or the required skills to monitor geothermal reservoirs properly.

Problems in the working process can also cause the land to sink over time. If there is no continuous tracking of underground pressure or if land deformation surveys happen only once in a while, warning signs may be missed. Poor reservoir management is another major cause. When more geothermal fluid is taken out than what is put back, or when reinjection is not planned well, the underground layers lose support. This leads to long-term sinking that is difficult to control.

Issues with equipment and materials make the situation even more serious. Reinjection wells may become blocked, pumps may not match the required capacity, and pressure sensors may stop giving accurate readings if they are not maintained on time. The materials inside the wells can also weaken. Steel casings can corrode because of hot and acidic fluids, and silica or mineral deposits can reduce underground water flow. When this happens, the land above becomes more likely to sink.

A strong and organized investigation is needed to understand all these causes. This is where ProSolvr becomes extremely valuable. ProSolvr helps teams visually explore the problem using fishbone or fault tree based Visual Root Cause Analysis, which makes even complex geothermal issues easy to understand. It also supports Virtual Collaboration, allowing teams in different locations to work together, share information quickly, and make better decisions. After the true causes of subsidence are identified, ProSolvr guides teams in creating effective Corrective and Preventive Actions, or CAPA. With ProSolvr, organizations can solve problems with more confidence and greatly reduce the chances of land subsidence happening again.

Who can learn from the Land Subsidence template?

- Geothermal Plant Engineers and Technicians: They can gain insights into how operational practices, reinjection balance, and equipment maintenance influence ground stability and reservoir performance.

- Environmental and Geoscience Professionals: They can better understand the geological and hydrological interactions that contribute to subsurface deformation and how sustainable extraction practices can mitigate such risks.

- Project Managers and Energy Planners: They can learn the importance of integrating risk assessment and sustainable design principles into geothermal project planning and execution.

- Quality Assurance and Compliance Teams: These professionals can see how structured RCA and CAPA frameworks help ensure adherence to regulatory standards, operational guidelines, and safety requirements.

- Policy Makers and Regulatory Authorities: By studying the RCA, they can recognize the need for enforcing stricter monitoring, reporting, and reinjection balance policies to prevent future subsidence incidents.

- Training and Development Coordinators: They can use the findings to design targeted capacity-building programs that enhance workforce competence in geothermal operations, safety, and environmental stewardship.

Why use this template?

ProSolvr allows multidisciplinary teams to map out issues and visually connect them to their consequences. ProSolvr's intelligent structuring and guided CAPA generation can help organizations implement data-backed, actionable solutions efficiently. By transforming qualitative insights into structured RCA outputs, ProSolvr empowers engineers and managers to foster continuous improvement, ensuring safer, more sustainable geothermal operations.

Use ProSolvr by smartQED to eliminate issues in the geothermal domain for effective renewable energy production.