RCA of Instrumentation Failures

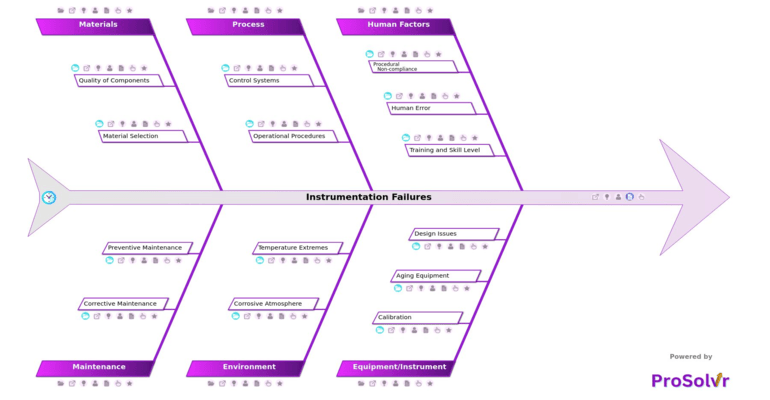

Instrumentation failures in petrochemical plants can lead to significant disruptions, including unsafe operating conditions, production delays, and increased downtime. These failures often stem from various factors, including human error, equipment issues, environmental factors, and maintenance gaps. For instance, procedural non-compliance, such as skipping steps in outdated maintenance procedures or misinterpreting sensor data, can cause systems to malfunction. Additionally, a lack of proper training or human error during calibration can further exacerbate the issue.

A common cause of instrumentation failures is calibration drift, where infrequent calibration schedules or aging equipment lead to inaccurate readings and faulty system decisions. Aging equipment, such as wear and tear or the end of lifecycle issues, also contributes to failures. Furthermore, design flaws in instruments, such as poor interface design or inadequate resilience in harsh operational environments, can make equipment more susceptible to failure.

Environmental conditions play a crucial role in triggering instrumentation issues. Corrosive atmospheres, such as high humidity or exposure to aggressive chemicals, can lead to equipment degradation. Similarly, temperature extremes cause thermal cycling, which can weaken components and result in failures. These environmental factors, combined with material degradation, further contribute to the vulnerability of critical instrumentation systems.

Finally, gaps in maintenance practices are significant contributors to instrumentation failures. Delays in addressing known issues, along with inadequate preventive maintenance schedules, allow minor problems to escalate into major failures. Regular checks and timely repairs are essential for maintaining equipment reliability and minimizing operational risks.

Using a GEN-AI-powered root cause analysis (RCA) tool like ProSolvr can help identify and address the various factors by systematically analyzing contributing causes and mapping them out. ProSolvr uses fishbone diagrams and AI-driven insights to visually identify root causes, helping teams develop targeted Corrective and Preventive Actions (CAPA) to improve equipment performance. With ProSolvr, teams can proactively identify maintenance gaps and optimize their schedules, ensuring that corrective actions are taken before failures occur and minimize the downtime.

Who can learn from the Instrumentation Failures template?

- Plant Engineers and Technicians: Responsible for maintaining and troubleshooting equipment in petrochemical plants, they can use the template to identify and analyze causes of instrumentation failures.

- Maintenance Teams: Tasked with performing both corrective and preventive maintenance, they can utilize the template to plan and execute effective maintenance strategies based on identified failure causes.

- Process Safety Managers: Focused on ensuring safe operations, they can use the template to investigate failures that could lead to safety hazards and develop preventive measures.

- Quality Assurance (QA) Teams: Involved in ensuring the reliability and accuracy of instrumentation, QA teams can use the template to audit and improve processes and equipment performance.

- Operations Managers: Responsible for overseeing daily plant operations, they can leverage the template to enhance operational procedures and minimize downtime due to instrumentation issues.

- Training and Development Coordinators: Focused on training staff, they can use the template to identify gaps in skills and knowledge and tailor training programs to address common human errors related to instrumentation failures.

Why use this template?

Root Cause Analysis (RCA) using a visual RCA tool like ProSolvr for instrumentation failures provides significant benefits by enabling organizations to systematically identify the underlying causes of issues, rather than just addressing their symptoms. By thoroughly analyzing factors such as equipment design, human error, maintenance practices, and environmental conditions, Gen-AI powered RCA helps prevent recurring failures, leading to more reliable and efficient operations. It also enhances safety by uncovering potential hazards that may not be immediately obvious. Besides, RCA supports continuous improvement by informing better decision-making in equipment selection, training, and maintenance planning, ultimately reducing downtime, saving costs, and ensuring consistent process performance.

Use ProSolvr by smartQED to effectively analyze instrument and equipment issues in your plant by customizing your templates.