RCA of Heat Exchanger Failures

Heat exchanger failure in compressor plants refers to the malfunction or degradation of heat exchangers, which are critical components used to transfer heat between two or more fluids. In compressor plants, heat exchangers play a vital role in managing the temperature of process fluids, which can be crucial for efficient operation and maintaining product quality. When a heat exchanger fails, it can significantly impact the plant’s performance and safety. Addressing these factors helps in maintaining the reliability and efficiency of heat exchangers, thereby ensuring smooth and safe operation of the compressor plant.

Consequences of Heat Exchanger Failures in Petrochemical Plants

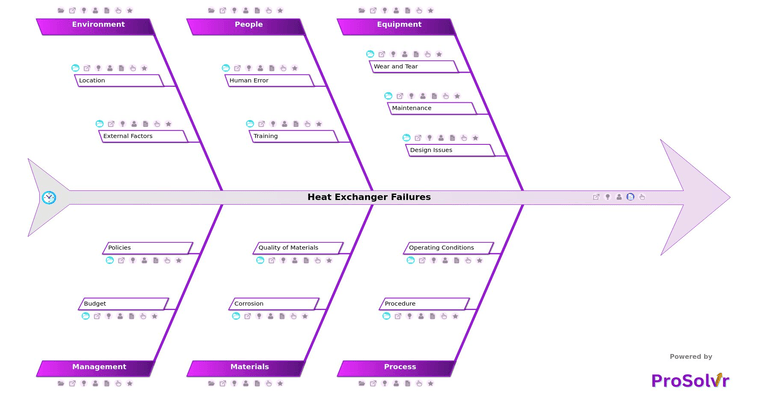

Root cause analysis (RCA) using fishbone diagrams provides significant benefits for addressing heat exchanger failures in compressor plants. Fishbone diagrams, also known as Ishikawa diagrams, facilitate a structured approach to identifying the underlying causes of failures by categorizing potential issues into various factors such as equipment, processes, materials, and human factors. This visual RCA tool helps teams systematically analyze and trace the root causes of heat exchanger malfunctions, such as fouling, corrosion, or leaks. By breaking down complex problems into more manageable components, the fishbone template enhances understanding and highlights interrelationships between different factors, enabling more effective troubleshooting and targeted solutions.

Who can learn from the Heat Exchanger Failures template?

- Maintenance Personnel: Maintenance teams can gain valuable insights into the common causes of heat exchanger failures and learn best practices for preventive maintenance and troubleshooting. Understanding the root causes helps them perform more effective inspections and repairs, reducing downtime and improving system reliability.

- Engineers and Process Designers: Engineers and process designers can use the findings from RCA to improve the design and specifications of heat exchangers. Insights from failures can inform better design practices, material selection, and system integration, enhancing the robustness and efficiency of future designs.

- Operations Staff: Operations personnel can benefit from understanding how operational practices and procedures impact heat exchanger performance. Learning about failure modes and contributing factors helps them adjust operational parameters and avoid conditions that could lead to failures.

- Safety Managers: Safety managers can use the insights from RCA to identify potential safety risks associated with heat exchanger failures. Understanding failure modes and their consequences allows them to develop better safety protocols and emergency response plans to mitigate risks.

- Training and Development Teams: Training and development teams can incorporate the lessons learned from RCA into their training programs. By including real-world examples of heat exchanger failures and their root causes, they can better prepare staff for effective problem-solving and maintenance strategies.

Why use this template?

Using Gen-AI powered root cause analysis promotes a collaborative problem-solving environment. The process encourages input from various stakeholders, including engineers, maintenance staff, and operators, who bring diverse perspectives and expertise to the analysis. This collective approach not only helps uncover less obvious causes but also fosters a culture of continuous improvement and shared responsibility. By addressing the root causes identified through a quality tool, petrochemical plants can implement more precise corrective, preventive and investigative actions, reduce the likelihood of recurrence, and enhance the overall reliability and efficiency of their heat exchangers.

Use ProSolvr by smartQED in your plant for effective problem analysis and resolution.