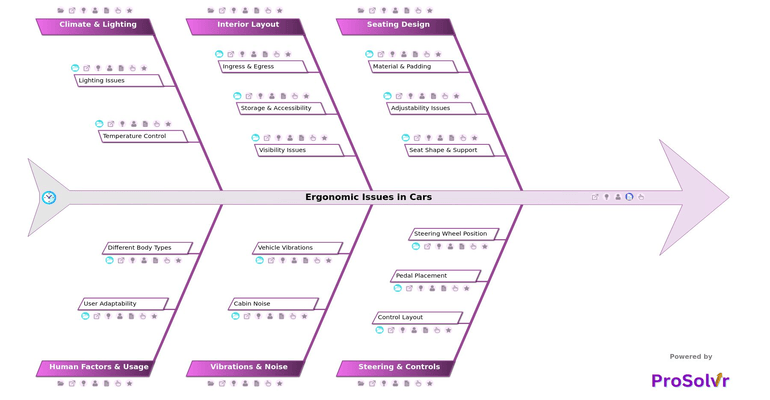

Root Cause Analysis of Ergonomic Issues in Cars

Ergonomic issues in cars are a significant concern in automotive design, impacting driver comfort, safety, and overall vehicle usability. Problems like poor seating design, ineffective control layouts, and inadequate visibility can lead to discomfort, fatigue, and even long-term health issues for drivers. For example, non-breathable materials in seats can cause excessive sweating, while heat-retaining fabrics contribute to discomfort during long drives. Similarly, incorrect seat contouring, poor lumbar support, and insufficient seat adjustability (such as a lack of memory settings for different drivers) can lead to chronic back pain and driver fatigue. Additionally, improper pedal height and uneven spacing between pedals can cause ankle strain, further diminishing driver comfort and increasing the risk of fatigue.

In addition to seating issues, the control layout can significantly impact the driving experience. Small or poorly labeled buttons, touchscreen reliance that leads to driver distraction, and hard-to-reach dashboard controls create inefficiencies that reduce driver focus and reaction time. The steering wheel can also contribute to ergonomic problems when it’s positioned incorrectly, or when the steering column is too thick, obstructing leg movement. On top of this, improperly positioned mirrors that lead to blind spots, thick pillars obstructing the field of view, and poor windshield angles causing glare all compromise visibility, creating potential safety hazards.

Furthermore, issues related to ingress and egress—such as a low roofline causing head bumps while entering or high step-in height that makes it difficult for shorter drivers to get in—can exacerbate ergonomic inefficiencies. Similarly, storage accessibility, such as hard-to-reach cup holders or poorly positioned armrests, further undermines comfort and usability. Even vibrations caused by poor suspension or engine vibrations transmitted through the seat can contribute to discomfort, as can excessive cabin noise from improper sealing and poor insulation.

Addressing these recurring ergonomic failures requires a structured approach to identify and correct root causes. A GEN-AI-powered root cause analysis with ProSolvr, using a fishbone diagram aligned with Six Sigma principles, provides a methodical way to uncover the underlying issues. By categorizing these issues into specific areas—such as seating design, controls, visibility, and comfort—automotive manufacturers can identify patterns of recurring failures and implement targeted Corrective and Preventive Actions (CAPA) to resolve them. This structured problem-solving approach ensures that ergonomic deficiencies are not only fixed but permanently prevented.

Who can use the Ergonomic Issues in Cars template?

- Automotive Engineers & Designers: Understanding RCA helps them identify design flaws related to seating, steering controls, pedal placement, and visibility to improve ergonomics in future vehicle models.

- Manufacturing & Quality Assurance Teams: RCA allows them to trace ergonomic defects to production processes, material selection, or assembly errors, ensuring better quality control and fewer recalls.

- Occupational Health & Safety Professionals: These professionals can analyze ergonomic issues that contribute to driver discomfort, fatigue, or long-term injuries, helping advocate for better vehicle designs and work conditions for professional drivers.

- Fleet Managers & Logistics Companies: RCA can help them understand how poor ergonomics impact driver performance, safety, and retention, leading to better vehicle selection and modification strategies for commercial fleets.

- Consumer Advocacy & Regulatory Bodies: Learning from ergonomic RCA enables them to evaluate automotive safety standards, push for better regulations, and advocate for user-friendly vehicle designs based on real-world issues.

Why use this template?

A visual Gen AI powered root cause analysis application such as ProSolvr, which integrates fishbone diagram analysis, can significantly enhance problem resolution in automotive ergonomics. ProSolvr enables manufacturers to categorize ergonomic issues visually, ensuring that all potential causes are explored in depth. By mapping the root causes and their interdependencies, decision-makers can formulate precise CAPA strategies. By addressing issues at their source, manufacturers can avoid costly redesigns after product launch and ensure that future models incorporate ergonomic improvements proactively.

Use ProSolvr by smartQED for solving ergonomic and other issues in your car manufacturing organization.