Root Cause Analysis of Engine Oil Leaks

Engine oil leaks are a common yet significant problem in automotive systems, often leading to engine damage, reduced vehicle performance, and environmental hazards. These leaks typically result from worn-out gaskets, damaged seals, or oil pan defects. When oil escapes from the engine, it not only creates a mess but also jeopardizes essential engine lubrication, which is crucial for smooth operation. Continuous oil leaks can cause severe issues like oil depletion, overheating, increased friction, and potentially catastrophic engine failure.

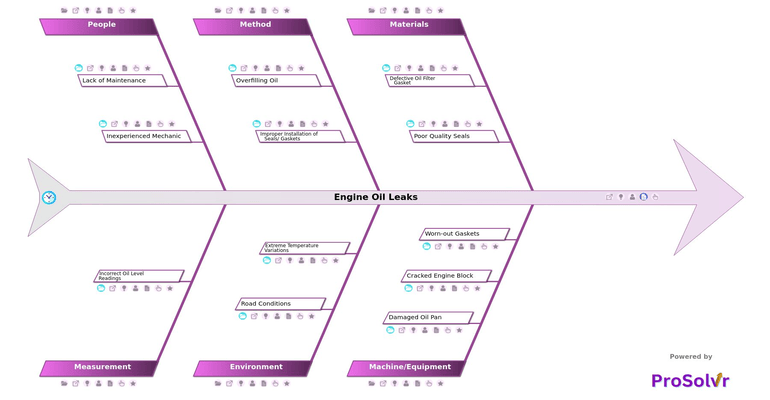

Addressing engine oil leaks promptly is vital for maintaining vehicle reliability and preventing engine damage. Conducting Root Cause Analysis (RCA) using tools like the fishbone diagram (also known as the Ishikawa diagram) helps diagnose the problem effectively. ProSolvr provides a structured method to break down potential causes of oil leaks into categories. This approach allows automotive engineers and mechanics to systematically explore all possible causes and identify the root of the issue.

Once the root cause is found, corrective and preventive actions (CAPA) can be taken, such as replacing faulty components, ensuring correct installation procedures, or improving routine maintenance practices. Additionally, educating teams on early detection and using better-quality materials can prevent future oil leaks. By addressing every aspect of the problem, RCA ensures a comprehensive strategy to eliminate leaks and reduce the chance of recurrence.

Who can learn from the Engine Oil Leaks template?

- Automotive Technicians & Mechanics: This template helps diagnose oil leaks quickly by organizing potential causes and providing efficient troubleshooting methods.

- Engineers & Designers: Engineers can use this template to identify manufacturing flaws or material weaknesses, improving vehicle designs.

- Fleet Managers: Fleet management teams can leverage the template to minimize vehicle downtime and enhance operational efficiency by resolving oil leaks across multiple vehicles.

- Quality Assurance (QA) Teams: QA professionals can use the template to investigate defects found during production or post-sale, ensuring higher quality standards.

- DIY Car Owners: Auto enthusiasts can benefit by systematically analyzing why oil leaks occur and taking corrective action, such as replacing worn-out parts.

Why use this template?

ProSolvr, powered by Generative AI, accelerates the root cause analysis process by simplifying the investigation of engine oil leaks. This template helps teams visually map out potential causes using a fishbone diagram, facilitating collaboration among mechanics, engineers, and QA teams. It enables faster resolutions, improves accuracy, and prevents recurring oil leak issues, enhancing overall vehicle performance and reliability.

Use ProSolvr by smartQED to diagnose and resolve engine oil leaks efficiently, enhancing vehicle performance and ensuring long-term reliability and safety.