Root Cause Analysis of Emission Failures

Emission failures occur when vehicles exceed regulated emission standards, releasing harmful pollutants like carbon monoxide, nitrogen oxides, and particulate matter. In the automotive industry, these failures result from a combination of workforce inefficiencies, flawed testing methods, substandard materials, equipment failures, environmental factors, and ineffective management. Beyond environmental damage, emission failures lead to regulatory fines, recalls, reputational damage, and legal liabilities—making it crucial for manufacturers to identify and eliminate their root causes.

For instance, workforce inefficiencies, such as poor coordination between departments and high turnover of skilled workers, often lead to misinterpretation of test results or insufficient attention to detail during emission testing. A lack of training on emission standards and improper handling of testing equipment further contribute to inaccuracies. Additionally, outdated testing procedures, over-reliance on manual quality control processes, and errors in emission data logging compromise compliance, allowing non-compliant vehicles to pass through production.

Material-related issues also play a critical role in emission failures. Supply chain disruptions often lead to delays in sourcing compliant parts or inconsistent quality from suppliers. The use of non-compliant materials, defective engine components, and substandard catalytic converters results in vehicles failing emission tests despite passing internal inspections. Meanwhile, engine design flaws, calibration issues in testing equipment, and poor maintenance of diagnostic tools further reduce the accuracy and reliability of emission control measures. External factors such as dust and pollutants interfering with test results or high ambient temperatures affecting emissions readings add additional complexity to the problem.

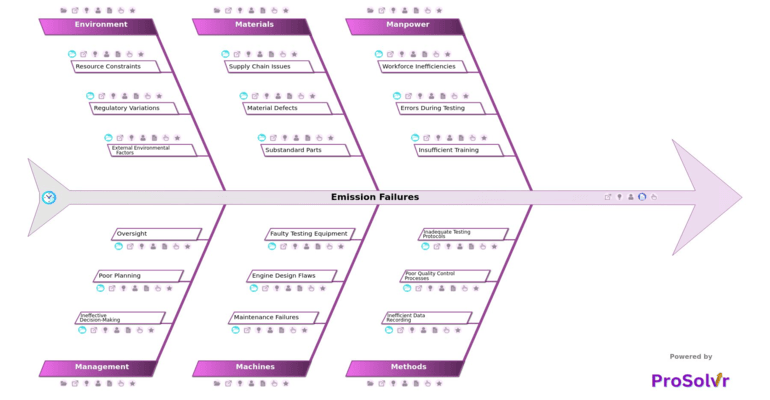

A Gen AI-powered Root Cause Analysis (RCA) application like ProSolvr enables automotive manufacturers to systematically analyze and prevent emission failures. Using Fishbone Diagrams, ProSolvr categorizes issues into key areas—manpower, methods, materials, machines, environment, and management—providing a structured problem-solving approach. By implementing Corrective and Preventive Actions (CAPA) based on these insights, manufacturers can strengthen compliance, improve emission control measures, and reduce regulatory risks. With ProSolvr’s RCA capabilities, emission failures don’t just get resolved—they get permanently eliminated.

Who can use the Emission Failures template?

- Engineering and Design Teams: These teams can learn how design flaws, such as engines not aligned with emission norms or poorly optimized systems, contribute to failures. Understanding these issues helps them create better, compliant designs for future vehicles.

- Quality Assurance and Testing Teams: QA teams can identify weaknesses in testing protocols, such as non-compliance with updated regulations or errors in data logging. Insights from RCA help them refine their testing processes and implement stricter quality control measures.

- Supply Chain and Procurement Managers: RCA findings on material defects, delays in sourcing compliant parts, and inconsistent supplier quality can guide procurement managers to choose more reliable suppliers and enforce stricter material compliance checks.

- Production and Maintenance Teams: These teams can learn about the impact of irregular machinery servicing, inadequate diagnostic tools, or outdated emission testing equipment. RCA helps them schedule maintenance more effectively and ensure equipment is updated and calibrated.

- Regulatory Compliance Officers: Insights into issues like delays in adopting updated regulations or differing global emission standards help compliance officers ensure that their company’s practices align with local and international emission laws.

- Management and Leadership Teams: Management can understand how poor planning, ineffective decision-making, and lack of proactive responses to regulatory changes contribute to failures. This knowledge enables them to allocate resources more effectively and prioritize compliance initiatives.

Why use this template?

While emission failures pose significant challenges, GEN-AI-powered root cause analysis tools like ProSolvr offer a methodical and efficient way to resolve underlying issues and enhance the industry's ability to meet emission standards. By addressing root causes and implementing CAPA, organizations can mitigate risks, protect their reputation, and contribute to a cleaner environment.

Use ProSolvr by smartQED for efficient problem-solving in your automobile plants.