RCA of Electrical Short Circuit

An electrical short circuit happens when current flows through an unintended path with little or no resistance, usually due to faulty wiring, damaged insulation, or contact between conductors. This sudden surge of current can generate excessive heat in the circuit. As a result, it may damage equipment, melt wires, or even start a fire. Short circuits can also cause electrical shocks that pose serious safety risks to people. In industrial and power systems, they may lead to large-scale outages and equipment failures.

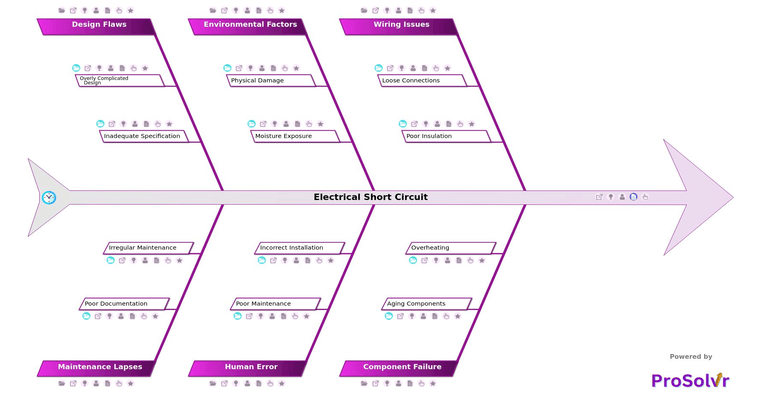

The main categories often include methods, materials, equipment, environment, and people, which can be customized to fit the specific context. Teams might examine the condition of wiring, the quality of circuit components, and the presence of any physical damage using the template. Factors such as humidity, temperature fluctuations, or the presence of conductive dust might also be considered. By dissecting the problem in this manner, teams can pinpoint specific areas that require attention, thus enhancing the efficiency and effectiveness of the root cause analysis process.

A Gen-AI powered fishbone diagram, also known as an Ishikawa or cause-and-effect diagram, can be indispensable for the root cause analysis of the factors leading to an electrical short circuit. By visually organizing potential causes into different categories using Six Sigma principles, it helps teams systematically consider various aspects that might contribute to the problem. Teams might examine the condition of wiring, the quality of circuit components, and the presence of any physical damage using the template.

This comprehensive approach ensures that no potential cause is overlooked, facilitating a thorough investigation. Using a Gen-AI powered, visual RCA application like ProSolvr allows teams to break down the problem into manageable parts, making it easier to analyze each potential cause individually and implement robust CAPA.

Who can learn from the Electrical Short Circuit template?

- Electrical Engineers: They can use the insights gained from the analysis to improve the design and maintenance of electrical systems, ensuring better reliability and safety.

- Maintenance Technicians: Understanding the root causes of electrical short circuits helps technicians perform more effective preventative maintenance and troubleshoot issues more efficiently.

- Quality Assurance Teams: These teams can use the findings to develop and implement standards and procedures that minimize the risk of electrical faults and enhance overall product quality.

- Project Managers: By learning about potential risks and their causes, project managers can better plan and allocate resources to mitigate these risks during the project lifecycle.

- Safety Officers: Safety officers can use the analysis to identify and address hazards, improving workplace safety protocols and reducing the likelihood of electrical accidents.

- Training and Development Coordinators: These professionals can design targeted training programs for staff based on the identified root causes, enhancing their knowledge and skills in preventing and addressing electrical issues.

- Product Designers: Insights from the analysis can inform the design process, leading to the development of products that are less prone to electrical short circuits and more robust in various operating environments.

Why use this template?

The collaborative nature of developing a Gen-AI powered RCA template encourages input from various stakeholders, fostering a more comprehensive understanding of the problem. Different team members might bring unique perspectives and expertise, leading to the identification of causes that might otherwise be missed. The collaboration aids in identifying the root causes and also in developing a shared understanding of the problem, which is crucial for implementing effective solutions.

By addressing the root causes identified through the quality and reliability tools like ProSolvr by smartQED teams can take targeted actions to prevent future occurrences of several issues in their organization.