RCA of Boiler Tube Leaks

Boiler tube leaks in thermal power plants occur when the tubes that carry water or steam inside the boiler develop cracks, ruptures, or corrosion-induced holes. These leaks are a serious issue because they disrupt the heat transfer process, lower boiler efficiency, and can force an unexpected plant shutdown. In severe cases, boiler tube leaks can lead to safety hazards, costly repairs, prolonged downtime, and reduced power generation capacity, directly impacting both operational reliability and economic performance.

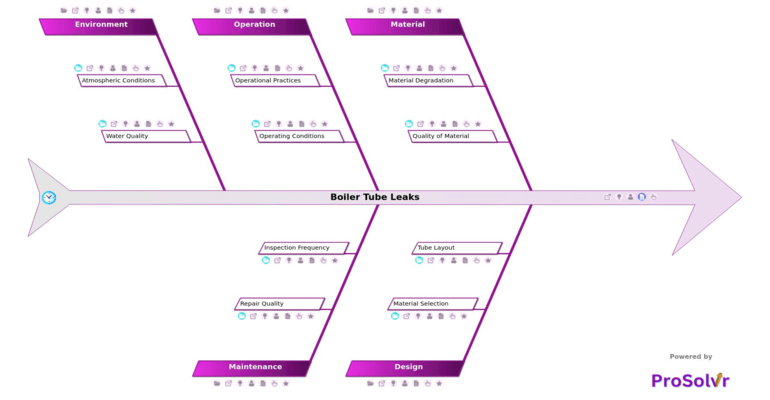

A fishbone template can be invaluable for conducting root cause analysis of various issues in a thermal power plant, like boiler tube leaks. By breaking down the problem into various contributing factors, the Gen-AI powered RCA enables maintenance teams to focus on all possible angles, ensuring that no potential cause is overlooked. It facilitates a structured brainstorming process, where team members can collectively analyze and list possible reasons for the leaks, such as material defects, operational errors, maintenance issues, environmental factors, and design flaws.

In a thermal power plant, multiple departments such as operations, maintenance, engineering, and quality control need to work together to resolve complex issues like boiler tube leaks. A Gen-AI powered root cause analysis application like ProSolvr encourages cross-functional collaboration and fosters a culture of continuous improvement. By mapping out the various causes and their associated sub-causes, the Ishikawa diagram provides a clear and comprehensive view of all potential factors, making it easier to pinpoint the root causes of the boiler leaks.

ProSolvr's systematic approach helps thermal power plants in prioritizing the most critical issues that need immediate attention and formulating effective corrective actions.

Who can learn from the Boiler Tube Leaks template?

- Operations and Maintenance Teams: These teams are directly responsible for the daily functioning and upkeep of the plant. This knowledge helps in enhancing the efficiency and reliability of the plant operations, reducing downtime, and extending the lifespan of the equipment.

- Engineering Teams: Engineers can benefit from RCA by gaining insights into design flaws or material weaknesses that contribute to boiler leaks. This information is crucial for making design improvements, selecting more suitable materials, and incorporating better safety and reliability features into future projects.

- Design Teams: Learning from past issues enables design teams to create more robust and leak-resistant boiler systems, thereby improving overall plant performance and safety.

- Management Personnel: Senior management can use the findings from the RCA to make informed strategic decisions. Understanding the root causes of boiler leaks allows them to allocate resources more effectively, prioritize maintenance and upgrade projects, and develop comprehensive risk management strategies.

- Policy Makers: This knowledge also helps decision-makers in creating policies and procedures that promote a culture of continuous improvement and proactive problem-solving, ultimately leading to enhanced operational efficiency and reduced costs.

Why use this template?

The visual nature of the RCA template helps in presenting the problem and its causes in a way that is easily understandable by all stakeholders, facilitating better communication and coordination. Quality tools like ProSolvr from smartQED aid in reducing downtime, improving the reliability of the boiler system, and enhancing the overall efficiency of the thermal power plant. By involving different perspectives, the analysis becomes more thorough and well-rounded, leading to more robust solutions.

Use ProSolvr by smartQED for understanding the root causes of various issues to improve your maintenance practices, adopt better operational procedures, and implement preventive measures to avoid future risks.