RCA of Chevron Oil Refinery Fire

The Chevron Oil Refinery Fire on October 2, 2025, at the El Segundo facility in Southern California raised major concerns because the refinery supplies a large portion of the region’s fuel. The fire began in the Isomax 7 jet fuel conversion unit and was brought under control within a day, but the incident still created serious operational challenges. Events like this show how quickly refinery systems can be affected by leaks, volatile hydrocarbons and equipment stress, and why strong safety practices are essential.

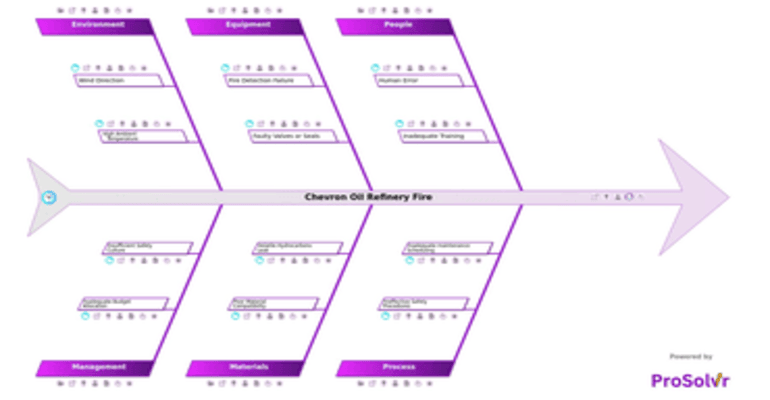

When investigators study incidents like the Chevron Oil Refinery Fire, they often find multiple contributing factors. People related issues can include human error such as failure to follow lockout and tagout procedures, improper valve operation, or inadequate training that leads to poor understanding of fire suppression systems and lack of emergency response drills. Process contributors may include outdated standard operating procedures, incomplete risk assessment for hot work, and delays in maintenance scheduling or inspection. These conditions increase the chance of small problems turning into major events.

Equipment and materials often play a significant role as well. Fire detection failure can happen because of sensor miscalibration or alarms that do not work, while faulty valves or seals may be caused by corrosion or lack of condition monitoring sensors. Materials such as aging pipelines, poor material compatibility or volatile hydrocarbons can lead to leaks and high vapor pressure mixtures. Environmental conditions, including wind direction or high ambient temperature, can make containment harder and allow fire to spread to nearby units. Management factors also matter, such as underinvestment in modernization, deferred maintenance funding, insufficient safety culture and lack of an incident learning system.

A platform like ProSolvr helps organizations review all these factors in a clear and structured way. With GEN AI powered Root Cause Analysis, combined with Fishbone diagrams and Six Sigma methods, teams can easily map every cause related to people, process, equipment, materials, environment and management. Each cause can be linked to the right corrective or preventive action, which makes investigations easier to understand and improves team collaboration. This approach supports stronger long term improvements in safety, reliability and overall operational excellence.

Who can learn from the Chevron Oil Refinery Fire template?

- Operations and Maintenance Teams: They can learn how procedural lapses, inadequate maintenance scheduling, and delayed inspections contribute to safety risks, helping them strengthen compliance and maintenance discipline.

- Health, Safety, and Environment (HSE) Departments: These teams can understand how gaps in training, emergency preparedness, and safety culture can escalate into major incidents, reinforcing the need for proactive hazard identification and mitigation.

- Engineering and Technical Teams: They can gain insights into how equipment design, material selection, and monitoring systems influence operational reliability, guiding improvements in engineering standards and system resilience.

- Management and Leadership: Leaders can learn the importance of prioritizing safety investment, promoting a strong safety culture, and ensuring that production goals never compromise risk management and employee protection.

- Training and Human Resources Departments: These groups can recognize the value of structured competency programs, continuous learning, and periodic safety drills to enhance workforce readiness and emergency response capabilities.

- Regulatory and Compliance Officers: They can use the lessons to refine inspection frameworks, audit protocols, and compliance requirements to ensure that safety, maintenance, and operational standards are consistently upheld across the organization.

Why use this template?

The Chevron El Segundo fire provides a stark reminder of how swiftly complex petrochemical systems can face cascading risk from factors across human, technical, material and management categories. A well-executed GEN-AI enabled RCA using a fishbone diagram and Six Sigma disciplines can convert such a crisis into an opportunity for lasting organizational resilience, safer operations, and reduced chance of future incidents.

Use ProSolvr by smartQED to systematically eliminate problems in the refineries and safeguard your infrastructure.