Boeing Starliner Spacecraft Issue Root Cause Analysis

In June 2024, a Boeing Starliner spacecraft carried NASA astronauts Butch Wilmore and Suni Williams to the International Space Station (ISS) on its Crew Flight Test. However, shortly after docking, several technical anomalies were detected. The engineers detected small helium leaks in the propulsion system and observed multiple reaction-control thrusters failing to fire as expected during approaches and maneuvers. Because of these issues, NASA made the difficult but safety-first decision to bring the Starliner capsule back to Earth uncrewed. The spacecraft performed a controlled autonomous re-entry and landed safely in New Mexico.

As a result, Wilmore and Williams remained aboard the ISS far longer than planned. Their return was deferred, and they were rescheduled to come back aboard a SpaceX Crew Dragon spacecraft instead. Although they were not in immediate danger, the decision underscored how serious the technical glitches were, raising concerns about the reliability of the spacecraft, and its viability for future crewed missions.

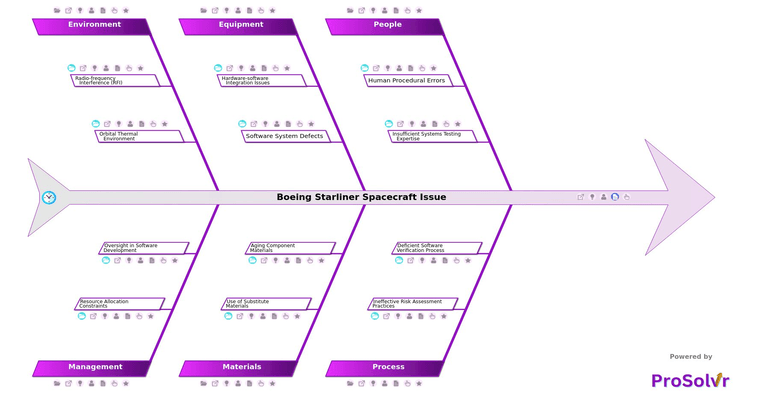

This incident shook confidence in the Boeing commercial crew program and highlighted persistent risks in crewed spaceflight development. It raised important questions about propulsion system integrity, quality assurance, and risk management. The issues, including helium leaks, thruster misfires, and a delayed astronaut return, show how small technical discrepancies can escalate into mission-level risks. Modern spacecraft involve tightly coupled systems where software timing, sensor drift, thermal effects, wiring degradation, or control logic inconsistencies can create failures that are difficult to trace.

This is exactly where ProSolvr transforms the investigation process.

Traditional RCA methods like fishbone diagrams and fault trees are powerful, but they become slow and complex when teams face thousands of signals, subsystems, and failure interactions. A Gen-AI powered RCA platform like ProSolvr strengthens the investigation from the start. It guides engineers through structured fishbone analysis and highlights hidden links between technical, process, and human factors that are easy to miss.

ProSolvr visually connects symptoms such as thruster anomalies, telemetry distortions, navigation interference, or thermal stresses to deeper causes such as timing mismatches, integration gaps, material degradation, supplier inconsistencies, or oversight in software development workflows. With clear, data-driven Corrective and Preventive Actions, ProSolvr helps aerospace teams improve reliability, reduce mission risks, and prevent similar failures in future spacecraft missions.

Who can learn from the Boeing Starliner Spacecraft Issue template?

- Aerospace Engineers: They can deepen their understanding of propulsion system behavior, integration challenges, and software hardware interactions that contributed to issues like thruster failures and helium leaks.

- Quality Assurance and Verification Teams: The RCA highlights gaps in end-to-end testing, software verification, and system-level simulations, helping these teams strengthen validation protocols.

- Flight Operations and Mission Control Staff: They can learn how procedural errors, missed cross-checks, and unexpected system responses affect mission planning, contingency management, and crew safety.

- Program and Project Managers: Insights into resource shortages, budget constraints, and oversight gaps help managers improve planning, risk assessment, and decision-making for future missions.

- Training and Development Teams: Causes such as insufficient systems testing expertise point to the need for enhanced training programs in spacecraft software, integrated systems, and mission-critical procedures.

- Safety and Risk Management Teams: The RCA provides valuable lessons on identifying systemic vulnerabilities, understanding cascading failure modes, and designing preventive strategies for crewed spaceflight missions.

Why use this template?

Applications like ProSolvr, built on structured fishbone analysis, take investigations to the next level. ProSolvr helps aerospace teams break down complex failures into clear, visual causal pathways, ensuring that no contributing factor is overlooked. By enabling a disciplined and methodical evaluation process, ProSolvr empowers engineers to create targeted CAPA plans that strengthen system reliability, improve verification procedures, and support safer, more dependable crewed missions.

Use ProSolvr by smartQED to systematically identify and eliminate issues in spacecraft systems, reduce costly rework, and prevent resource loss in future missions.

Curated from community experience and public sources: