Runway Excursion Root Cause Analysis

A runway excursion happens when an aircraft leaves the paved runway during take-off or landing, either by veering off the side or overrunning the end. Recent events like the runway excursion of Boeing 747-400 cargo flight EK9788 at Hong Kong International Airport, which hit a ground vehicle and ended up in the sea, remind us of the real danger. Similar cases such as Fly Jamaica Airways Flight 256 in Guyana and PenAir Flight 3296 in Alaska show that this risk exists even at well-equipped airports. Such incidents can cause serious damage to the aircraft, endanger lives, and disrupt airport operations.

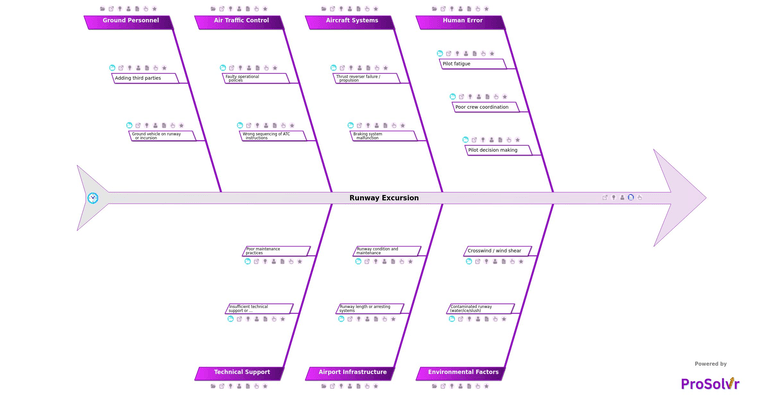

Many factors can lead to a runway excursion. Human error plays a key role. Issues like pilot fatigue, poor crew coordination, late go-around decisions, or unstable approaches increase the chance of losing runway control. Environmental factors such as a contaminated runway with water, ice, or slush can cause hydroplaning, reduced braking action, and loss of directional control. Crosswind and wind shear during landing can push the aircraft off course. Technical problems like anti-skid failure, brake overheating, or thrust reverser malfunction make stopping harder.

Airport infrastructure and operational issues can also contribute. Short runways, poor surface maintenance, and lack of arresting systems (EMAS) reduce safety margins. Mistakes in air traffic control sequencing, late landing clearance, or faulty dispatch planning can force unstable approaches. Weak technical support, incomplete maintenance records, or deferred repairs of brakes or reversers increase the risk further. Even ground vehicle incursions or NOTAM misinterpretations can lead to last-moment evasive action and loss of control.

To prevent such incidents from recurring, organizations must conduct a thorough Root Cause Analysis (RCA). Using ProSolvr, powered by Generative AI and a visual Fishbone (Ishikawa) diagram, investigators can quickly map every contributing factor like human, environmental, technical, and those related to infrastructure. Combined with Six Sigma methodology, this approach ensures structured, data-driven insights rather than guesswork. ProSolvr makes RCA faster and more precise, helping teams uncover true root causes, design effective Corrective and Preventive Actions (CAPA), and monitor their impact over time. With ProSolvr, organizations move from reactive fixes to lasting safety improvements, transforming lessons from runway excursions into safer operations and stronger aviation systems.

Who can learn from the Runway Excursion template?

- Flight Operations Teams: Pilots and flight crew can learn how pilot fatigue, poor crew coordination, and late go-around decisions can lead to runway excursions. This helps them improve communication, workload management, and stabilized approach practices.

- Air Traffic Control (ATC) Personnel: Controllers can see how wrong sequencing, late landing clearances, or weak SOPs in bad weather increase risk. With this learning, they can make better procedures and improve coordination and situational awareness.

- Maintenance and Technical Support Teams: Engineers can find how poor maintenance, missed inspections, or deferred repairs cause brake or thrust reverser failures. This helps build stronger maintenance checks and better troubleshooting methods.

- Airport Infrastructure and Operations Teams: Airport staff can learn the value of runway grooving, friction maintenance, and EMAS systems. Good runway design and surface care keep operations safe and reliable.

- Safety and Risk Management Teams: Safety officers can study how human, technical, and environmental issues work together to cause excursions. This helps them plan preventive measures and better CAPA strategies.

- Training and Human Factors Specialists: Trainers can use this RCA to design courses on pilot fatigue, CRM (Crew Resource Management), and decision-making under stress. These programs help create safer habits and better teamwork.

Why use this template?

By using this RCA template in ProSolvr, organizations can stop fixing symptoms and start solving real problems. ProSolvr helps find root causes across human, technical, environmental, and organizational areas.

With ProSolvr by smartQED aviation teams can prevent future runway excursions, protect lives, and reduce losses. It turns every investigation into a chance to learn, improve, and build safer skies.

Curated from community experience and public sources: