Malfunction of Coriolis Mass Flow Meter RCA

A Coriolis mass flow meter is a highly accurate device used to measure the mass flow rate of a fluid traveling through a pipe. It operates based on the Coriolis effect, where a vibrating tube deflects as fluid flows through it. This deflection is proportional to the mass flow rate, allowing for precise measurements. These meters are crucial for maintaining efficiency, safety, and reliability in processes such as blending, custody transfer, and chemical reaction monitoring.

In petrochemical plants, Coriolis mass flow meters are widely used to measure mass flow, density, and temperature of various fluids, including crude oil, natural gas, chemicals, and liquefied gases. Despite their accuracy, these meters can encounter issues such as vibration interference from nearby equipment, erosion or corrosion of meter tubes, build-up or clogging, density measurement errors due to multiphase flow, and calibration drift over time. These problems can lead to inaccurate readings, process inefficiencies, and safety hazards if not promptly addressed.

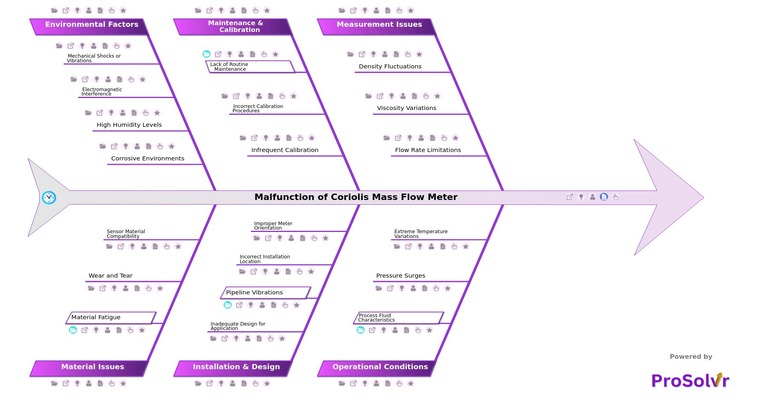

Conducting a root cause analysis (RCA) using a fishbone diagram helps identify and resolve these issues. Categorizing potential causes under specific headings allows teams to systematically explore and address each one. Vibration interference may stem from nearby machinery, prompting corrective action to isolate the meter. Erosion might require a review of material compatibility. This structured approach ensures all possible causes are considered, leading to more effective and targeted corrective actions.

Who can learn from the Malfunction of Coriolis Mass Flow Meter template?

Root Cause Analysis (RCA) of Coriolis Mass Flow Meter Malfunction provides valuable insights for various stakeholder

- Process Engineers: To improve process design and ensure accurate flow measurements by understanding potential issues and their causes.

- Maintenance Technicians: To identify common problems and implement preventive maintenance strategies, reducing downtime and repair costs.

- Quality Assurance Teams: To monitor and validate flow meter accuracy, ensuring product quality and compliance with industry standards.

- Safety Officers: To assess risks associated with meter malfunctions and develop safety protocols to prevent accidents and hazardous situations.

- Instrumentation Engineers: To fine-tune and calibrate the meters, ensuring their proper functioning within the plant's automation systems.

- Operations Managers: To oversee plant efficiency and make informed decisions regarding equipment upgrades or replacements based on historical malfunction data.

Why use this template?

Using root cause analysis for Coriolis mass flow meter malfunctions offers significant benefits by systematically identifying and addressing the underlying issues causing equipment failures. RCA helps pinpoint the exact factors leading to inaccuracies, such as vibration interference or calibration drift, which might otherwise be overlooked. By employing structured methods like fishbone diagrams or the 5 Whys technique, teams can explore all potential causes and their interconnections, leading to more effective and targeted solutions. This approach not only improves the reliability and accuracy of flow measurements but also enhances overall process efficiency, reduces downtime, and minimizes maintenance costs, contributing to smoother plant operations and better product quality.

Draft and create a template for problem analysis in ProSolvr by smartQED.