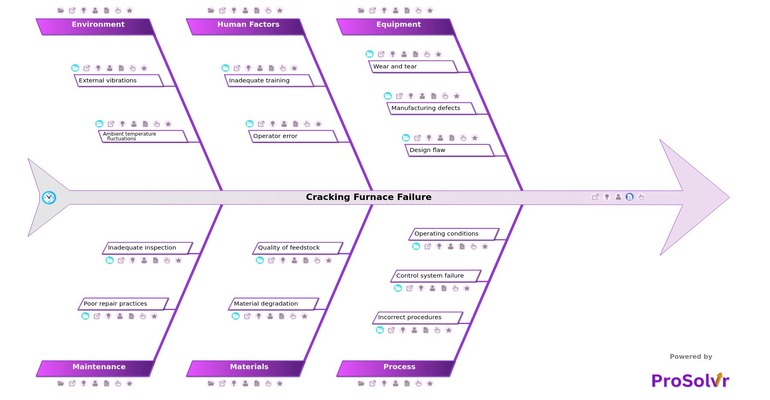

RCA of Cracking Furnace Failure

Using a fishbone diagram for Root Cause Analysis (RCA) in the case of a cracking furnace failure is crucial for systematically identifying, analyzing, and addressing root causes, enabling effective resolution and prevention of future incidents. A cracking furnace, also known as an ethylene furnace or pyrolysis furnace, is a critical component in petrochemical plants, particularly in producing basic building blocks like ethylene, propylene, and other olefins.

These furnaces are central to the process of steam cracking or thermal cracking, which breaks down large hydrocarbon molecules into smaller, more valuable ones. In petrochemical plants, cracking furnaces are used to convert naphtha or other hydrocarbons into ethylene and propylene, which are then used to produce polyethylene, polypropylene, and other essential petrochemical products.

The primary function of a cracking furnace is to thermally break down large, complex hydrocarbon molecules such as naphtha, ethane, or propane into smaller, simpler molecules like ethylene, propylene, and butadiene. This process occurs at extremely high temperatures, typically ranging from 750°C to 1,100°C (1,380°F to 2,000°F), in the presence of steam.

Impact of Cracking Furnace Failures

Cracking furnaces operate at very high temperatures and pressures. A breakdown might lead to:

- Uncontrolled Reactions:Increased risk of fires or explosions due to uncontrolled reactions.

- Chemical Leaks:Potential release of unprocessed hydrocarbons or hazardous chemicals, posing serious risks to plant personnel and the environment.

- Environmental Violations:Release of unburned hydrocarbons or pollutants, leading to environmental regulation violations, fines, or cleanup costs.

- Contamination:Hazardous material spills, leading to soil or water contamination.

- Operational Disruptions:Chain reactions of failures or operational issues in downstream equipment, causing extended downtime.

Who can learn from the Cracking Furnace Failure template?

The root cause analysis (RCA) of cracking furnace failure in a petrochemical plant can provide valuable insights to a wide range of stakeholders.

- Operations Team: Refine operational protocols and prevent similar incidents by understanding process deviations and equipment handling issues.

- Maintenance Team: Enhance inspection routines and timely replacement of critical components to avoid future breakdowns.

- Engineering Team: Improve furnace design, material selection, and engineering standards to enhance reliability and safety.

- Safety and Health Team: Develop stronger safety protocols, improve hazard identification processes, and enhance safety training.

- Management: Make informed decisions regarding resource allocation and prioritize critical infrastructure.

- Training and Development Team: Address training gaps to better prepare personnel for complex situations.

- Procurement and Supply Chain Team: Improve procurement practices and ensure proper specifications are met.

- Environmental Compliance Team: Strengthen environmental controls and ensure compliance with regulations.

- Quality Assurance Team: Enhance quality control measures and refine testing procedures.

- External Stakeholders: Evaluate compliance with safety standards and adjust risk assessments.

- Research and Development (R&D) Team: Drive research initiatives for more reliable and safer furnace operations.

- Crisis Management Team: Improve crisis management plans and communication protocols for future incidents.

Why use this template?

A root cause analysis using a fishbone diagram can be highly effective in identifying the underlying causes of a cracking furnace breakdown. This tool helps in narrowing down broad categories to specific root causes by asking "Why?" at each branch, leading to a deeper understanding of the problem. Prioritize critical issues first, and through brainstorming sessions with a cross-functional team, this Gen-AI powered fishbone diagram encourages collaboration, bringing diverse perspectives to identify causes that might not be immediately obvious.

Draft and create a template for problem analysis in ProSolvr by smartQED.